Why UV MB for Films is Essential for Packaging Industries

Why UV Masterbatch for Films is Essential for Packaging Industries

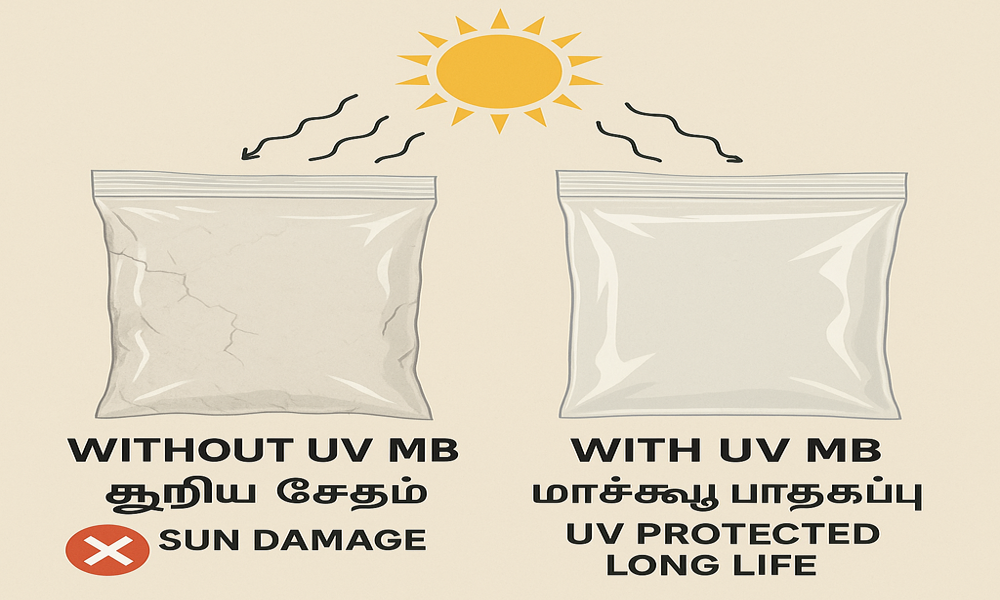

In the packaging industry, maintaining the integrity of products while ensuring their shelf life is one of the most crucial factors. One of the most effective ways to achieve this is by incorporating UV (ultraviolet) protection into packaging films. This is where UV masterbatch (MB) plays an essential role. UV masterbatches are specialized additives used to enhance the resistance of packaging films against the harmful effects of UV radiation. In this blog post, we’ll delve into why UV MB is crucial for the packaging industry, how it works to prevent material degradation, which industries benefit the most, and best practices for selecting the right masterbatch for films.

The Need for UV Protection in Packaging Films

UV radiation, present in natural sunlight, can be extremely damaging to materials exposed to it over time. In packaging, UV rays can cause several issues, such as:

-

Degradation of Material: UV rays break down the polymer chains in packaging materials like polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET). This can result in brittleness, discoloration, and loss of structural integrity.

-

Loss of Product Quality: UV exposure can degrade not only the packaging material but also the products inside. For instance, UV can alter the color, texture, and chemical composition of food products, pharmaceuticals, and cosmetics, leading to a reduced shelf life and compromised quality.

-

Aesthetic Damage: UV radiation can cause discoloration and fading of printed graphics, logos, and labeling on packaging. This can diminish the visual appeal of a product, reducing its marketability.

-

Safety Concerns: In some cases, UV radiation can contribute to the leaching of toxic substances from certain packaging materials. For products like food and pharmaceuticals, this could have serious health implications.

Therefore, UV protection is essential for maintaining the quality, appearance, and safety of both the packaging material and the contents it protects.

How UV Masterbatches Prevent Material Degradation

UV masterbatches are specialized additives that are incorporated into plastic films during the manufacturing process. These masterbatches contain UV stabilizers, absorbers, or blockers that act as shields against the harmful effects of UV radiation. Here’s how they work:

-

UV Absorption and Scattering: UV masterbatches contain chemicals that absorb harmful UV rays and convert them into less harmful forms of energy, such as heat. This prevents the UV radiation from penetrating deep into the material, where it could cause chemical degradation of the polymer.

-

Chemical Stabilization: UV stabilizers in the masterbatch react with the UV rays before they can break down the polymer chains, effectively “neutralizing” the potential damage. This enhances the longevity of the packaging material and ensures it maintains its physical properties over time.

-

Blockage of UV Rays: Some UV masterbatches are formulated to scatter or block UV light entirely, preventing it from even reaching the film surface. This makes them particularly valuable for applications requiring high levels of UV protection.

-

Durability: The use of UV MB increases the durability and performance of films, ensuring they do not become brittle or discolored after prolonged exposure to sunlight or artificial UV light sources.

Industries That Benefit from UV Masterbatches

Several industries benefit significantly from the use of UV masterbatches in their packaging films. These industries rely on packaging that maintains product quality, safety, and appearance despite prolonged exposure to UV radiation.

-

Food and Beverage Industry: Packaging for food and beverage products, especially those with delicate ingredients like oils, dairy, and juices, can be prone to UV degradation. UV exposure can lead to rancidity in oils or the destruction of vitamins (like Vitamin C) in juices. UV MB ensures these products maintain their quality and nutritional value while extending their shelf life.

-

Cosmetics and Personal Care: Packaging for cosmetic products like lotions, perfumes, and shampoos can undergo discoloration or degrade due to UV exposure. Additionally, the active ingredients in cosmetics can break down, losing efficacy. UV MB helps in maintaining both the visual appeal and functionality of the product.

-

Pharmaceuticals: The pharmaceutical industry often deals with medications that are highly sensitive to UV rays. UV MB can prevent the breakdown of both the packaging material and the drugs inside, ensuring they remain effective and safe for use.

-

Agriculture and Horticulture: Packaging for agricultural products, such as fertilizers, pesticides, and seeds, benefits from UV protection as it helps preserve the integrity of the contents. UV exposure can cause the packaging to degrade, leading to spillage or contamination.

-

Consumer Electronics: Packaging for sensitive electronics, such as components, gadgets, and batteries, often requires UV protection. UV rays can degrade the material and the product inside, leading to a reduced lifespan of electronic items.

-

Textiles and Apparel: UV masterbatches are also beneficial in packaging materials for textiles and clothing. The protection prevents packaging from becoming brittle and helps preserve the printed designs on the outer packaging.

Best Practices for Choosing the Right UV Masterbatch for Films

Selecting the right UV masterbatch for films is a critical decision that depends on several factors, such as the type of packaging, the level of UV protection needed, and the specific requirements of the product being packaged. Here are some best practices to consider:

-

Understand UV Protection Requirements: Different products and industries require different levels of UV protection. For example, food packaging may need stronger UV protection compared to other types of products. Understanding the specific UV exposure conditions, such as the intensity of light and the duration of exposure, will help in choosing the right type of masterbatch.

-

Material Compatibility: UV MB should be compatible with the specific polymer used for the film. Different polymers may require different types of UV stabilizers, so ensuring compatibility is crucial for achieving the best results.

-

Performance and Efficiency: Choose a UV masterbatch that offers a high level of UV protection without compromising the mechanical properties of the film, such as flexibility and strength. Ideally, the MB should enhance the performance of the film rather than detract from it.

-

Cost-Effectiveness: While high-quality UV MB may come at a premium, it is important to balance the cost with the desired performance. The right UV MB will provide long-term protection, reducing the need for costly product recalls or re-packaging due to material degradation.

-

Testing and Quality Assurance: Before selecting a UV masterbatch, it’s essential to test it in the actual packaging environment to ensure it meets the required standards. Look for suppliers that provide rigorous testing data to validate their products' effectiveness.

Conclusion

UV masterbatches play an indispensable role in safeguarding packaging materials from the harmful effects of UV radiation. By preventing material degradation, maintaining product quality, and extending the shelf life of packaged goods, UV MB ensures that both the packaging and the product inside remain intact and functional. Industries like food, pharmaceuticals, cosmetics, and agriculture benefit greatly from UV protection in packaging, making UV MB a vital component of modern packaging solutions. When choosing the right UV masterbatch, understanding the specific requirements of your application and selecting a compatible, effective, and cost-efficient option will go a long way in ensuring optimal performance.